Features

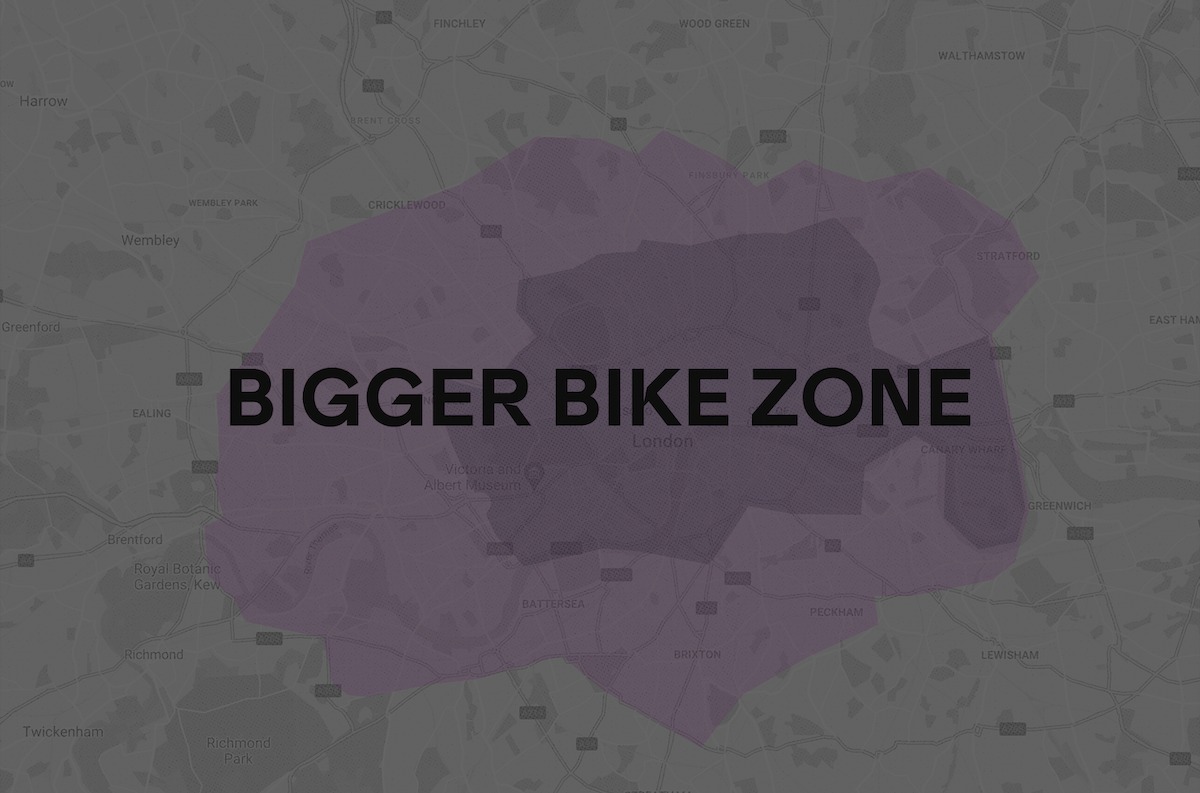

Stronger, faster, better: How electric bikes have helped us triple the size of our London bike zone

First up, what is the bike zone? It’s the designated area in London where your Gophr deliveries are eligible to be booked on push bikes or cargo bikes. And triple the size. Really? Yep 3x. Made…

Same Day Delivery comes in many different ‘flavours’

Same day delivery was once associated with bouquets of flowers, legal documents and forgotten keys. Fast forward a lockdown or three, with people demanding greater convenience, same day is fast…

Hub to Home: Bundled or unbundled?

There’s a maxim in delivery that the ‘last mile’ is the most difficult and expensive of all the miles. Estimates put it at 40 - 50% of the total fulfilment cost, and that’s before you factor in the…

Supporting our people and the planet

We think of sustainability as being two-fold; people and planet. We’ve always worked very hard at making sure we go further than others in our sector on the people side, making sure we do better by…

Learn the first steps to building the ultimate same-day logistics management platform

Updated: 22/12/19 Our same-day logistics management platform is fundamental to everything we do at Gophr. So, we thought we’d share how we built the brains of our business. We’ll explain how our…

Surcharges

SURCHARGES Certain surcharges may be payable by you in addition to the carriage fees which are set out as the cost for the standard delivery of your order. When a surcharge is payable, it may…